Composite Components

Fehrer has been manufacturing lightweight structures and composite components from fiberglass reinforced plastics since the 1980s.

Our product range includes crash-relevant components, adjustable rear backrest structures, and components that require high rigidity. Moreover, the intelligent combination of materials, process technology, and plant design enables us to explore new ways to reduce the weight of vehicle components.

Automotive lightweight construction

Global concerns surrounding climate change are driving the optimization of internal combustion engines and the development of alternative sources of propulsion in the automotive industry Lightweight construction is a crucial factor in both cases.

Future vehicle designs require the use of alternative material technologies, both for the interior and the body framework. They can be used to achieve maximum weight reduction without compromising requirements for passenger comfort and safety. Fehrer already uses a variety of technologies for the high-volume production of components for vehicle construction. Fehrer develops these technologies in-house and is working to further optimize them in terms of material properties and high-volume production processes.

Our composite specialists have developed engineering solutions based on rigid polyurethane foams, achieving record-breaking process and cycle times.

Composite Components

lightweight roof

An intelligent combination of PU fiber composite layers and a honeycomb core structure in a sandwich design make the roof module 30% lighter than conventional products.

Backpanel

Depending on design and construction requirements, different material technologies can be used. A weight-optimized mix offers new ways to go in then lightweight construction of vehicle seats.

Roof lining components

Our roof lining components visually enhance the feeling of being in the open air. Lining components for convertibles have been a firm part of our product offering for many years now.

Convertible top lids

Fehrer has developed production processes that permit a rigid component with low weight to be produced in a large-area design. The perfect example is the convertible top lid, which has to withstand high loading.

Backrest trim

This part features high rigidity, dimensional stability, and low weight. The material properties of the fiber reinforced plastics allow the customer a free hand in terms of visual design and decor.

Lightweight cushion frames

In contrast to conventional products, the new Fehrer rear seat frame from recycled carbon fiber composite materials brings together an entire range of functions in a single part. An edge strip channel, omega clamp, ISOFIX feedthrough, and attachment points for cupholders and trays are all integrated into the self-supporting cushion frame. This economizes on attachment parts, assembly steps, and weight—550 grams in total versus comparable standard products.

Multifunction divider

The divider, which separates the passenger area from luggage, drafts, and noise disruption, consists of three separate panels mounted on a crossmember, and is installed directly in the vehicle as complete module upon delivery. But the divider offers even more: the panels can be folded down variably, with a mechanically damped folding action. In this way, a normal luggage compartment can be transformed easily into a flat cargo space.

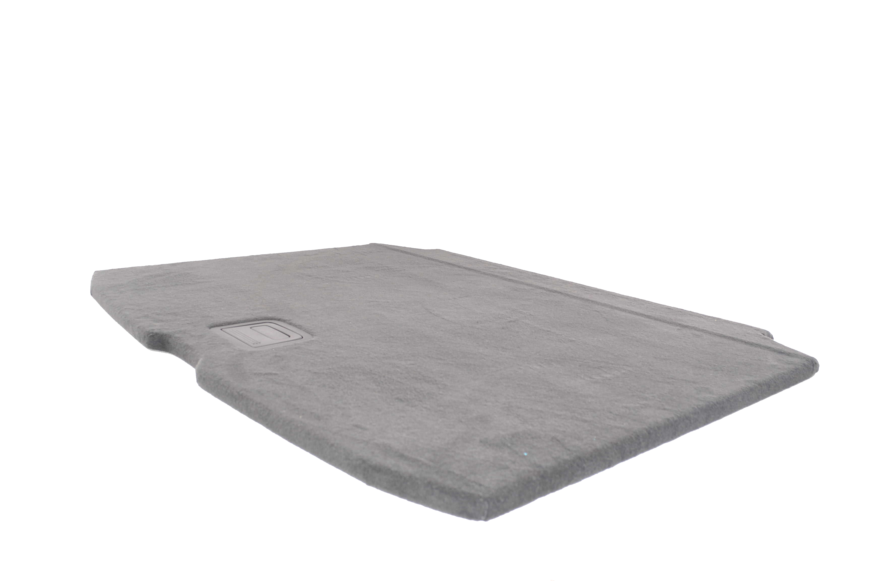

Load floors made of GF-PUR sandwich with paper honeycomb cores offer an optimum weight-to-stiffness ratio as well as good sound and heat insulation.

Whether single or multi-part systems, top and/or bottom decors, integration of loading space management - we develop the optimum solution according to customer requirements.

![{page.files.0,.properties.title} [Translate to English:]](/fileadmin/_processed_/b/9/csm_Galerie_Referenzen_Fehrer_e08f3ff777.jpg)